|

| September 08, 2020 | Volume 16 Issue 34 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Cobot vision system updated to handle quality inspection tasks

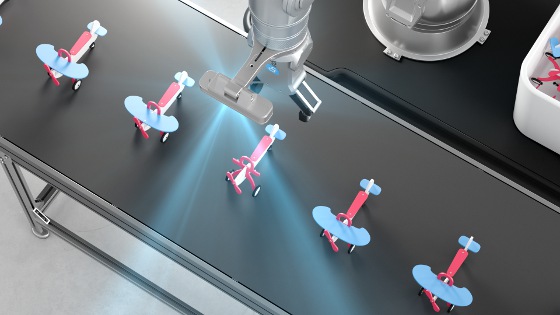

Just launched in April 2020, OnRobot's Eyes 2.5D camera-based vision system has already proven to be a bestseller for the company. The clever cobot arm add-on is ideal for sorting a wide variety of objects or for CNC machine tending with metal parts that are defined by outer shape, as well as many other pick-and-place applications where orientation is important.

New features for Eyes allow the technology to be deployed in quality inspection applications and on mobile robots. They include one-shot detection for multiple objects, color and blob detection, and automatic landmark calibration tools designed to speed cycle time for mobile robot setups.

"Our customers told us that they love Eyes' ease of use, but that they would like to see new features tailored to common quality inspection tasks. Today's Eyes update delivers that functionality," says Enrico Krog Iversen, CEO at OnRobot.

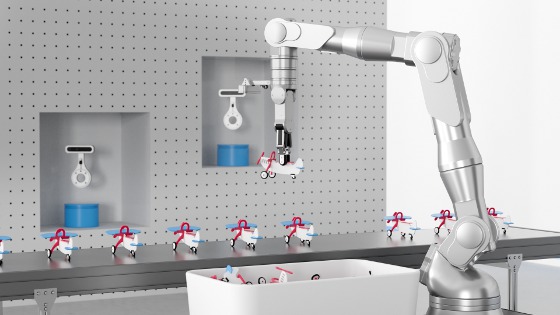

The Eyes system can be easily mounted on the robot wrist or externally, and it integrates seamlessly with all leading collaborative and light industrial robot arms through OnRobot's One System Solution, a unified mechanical and communications interface based on the company's Quick Changer, now an integrated part of all OnRobot products.

As opposed to other vision systems on the market, Eyes only needs to take a single image for calibration and part recognition, and it has automatic focus to work at different distances within the same application. This feature set has been improved.

Eyes' new inspection features enable the system to easily sort, inspect, or pick and place unstructured objects using color and contour detection -- a capability that is beyond most competing vision systems. This detection method requires no workpiece teaching and finds items based on color and size information input by the operator. Eyes' inspection features can be used to inspect parts removed from CNC machines, for example, or to check injection molding machine parts for excessive or inadequate material after the part has been molded. The tools also support manual inspections: Operators can set up a camera and inspection program, manually place a workpiece in view, and execute inspection. No robot required.

The update also provides users with one-shot detection for multiple objects, allowing the system to pick all workpieces with only one picture. This reduces complexity for users and improves cycle times. The update includes tools that allow users to request specific workpiece types and specify gripper clearance parameters.

The vision system directly interfaces with other OnRobot devices, making it is very easy to use Eyes together with any of OnRobot's grippers. With a dual setup, using a dual Quick Changer, the gripper's tool center point (TCP) can be automatically configured by Eyes, eliminating any potential conflict between different software packages from different tool vendors. The optimal mounting depends on the application. Advantages of having Eyes mounted externally include not having to worry about cables running alongside the robot and the ability to optimize cycle time, because Eyes can take the picture and process it while the robot is doing another operation.

Mobile robots can use Eyes too

A new Landmark feature has been added to Eyes' powerful toolkit, enabling easy deployment of Eyes on mobile robots and setups with carts, trays, and pallets. The Landmark feature makes it simple to program mobile robots to move from station to station using end-user-defined Landmarks as their guide. Landmarks can also be used to initiate specific robot operations: for example, when Eyes detects the arrival of a mobile cart in its workspace loaded with parts for picking, it can easily switch to pick-and-place routines.

"More and more manufacturers are looking to deploy robot arms on mobile platforms for various factory and warehouse applications," says Iversen. "Today's update gives our customers the ability to put 'Eyes' on mobile robots and does so without sacrificing the ease of use that makes our products such a compelling proposition for manufacturers of all sizes."

In many applications, single-purpose industrial robots are losing ground to affordable, easy-to-use robots and peripherals that can be flexibly redeployed for a wide range of tasks. This empowers manufacturers to gain even greater productivity increases from their automation investments.

"Traditional approaches to industrial automation place the product at the center, which results in costly, over-complicated solutions to simple automation problems," adds Iversen. "OnRobot takes a more practical, application-centered approach. This means providing our customers with easy-to-use tools tailored to specific application needs. But it also means empowering customers through updates to existing products that enable deployments in new application domains."

Source: OnRobot

Published September 2020

Rate this article

View our terms of use and privacy policy